Solving the Transfer Challenge

for MicroLED Display and Micro Semiconductor Fabrication at Scale

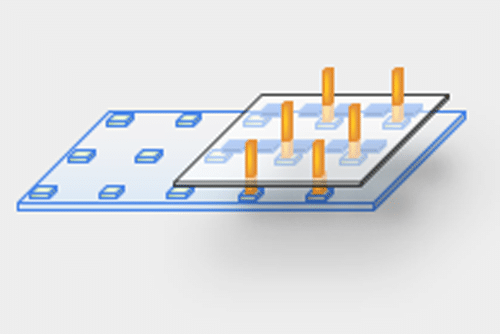

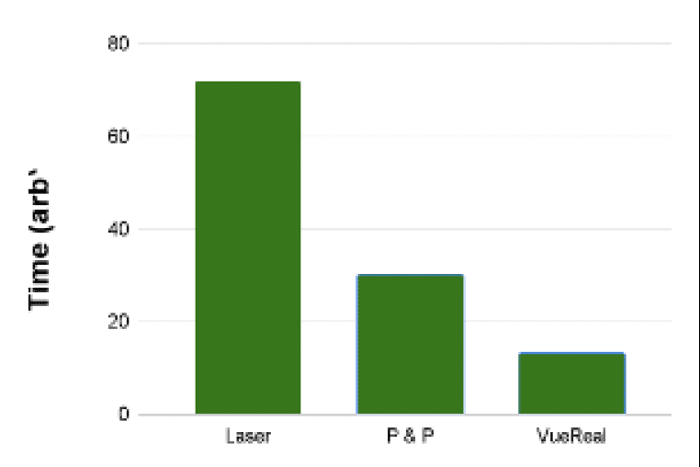

MicroSolid Printing™ Versus Laser and Pick and Place

MicroSolid Printing™ cracks the code in the efficient transfer of LEDs from wafer to backplane. With an initial focus on microLED displays, the platform will help enable a $30 billion market by 2030.The Problem:

Traditional methods like laser and pick-and-place are:Inefficient

Costly

Unscalable

Environmentally Unfriendly

The Solution:

MicroSolid Printing™: A scalable, eco-friendly turnkey approach that delivers unparalleled results over other transfer methods.Superior Performance

Exceptional visual quality and energy efficiency

Tunable transparency from 80% to zero

Versatile applications across industries

Unmatched Efficiency

99.999% yield rate

2-5 times higher throughput

Rapid placement of tens of millions of micro-LEDs

Cost-Effective Production

2-5 times more economical

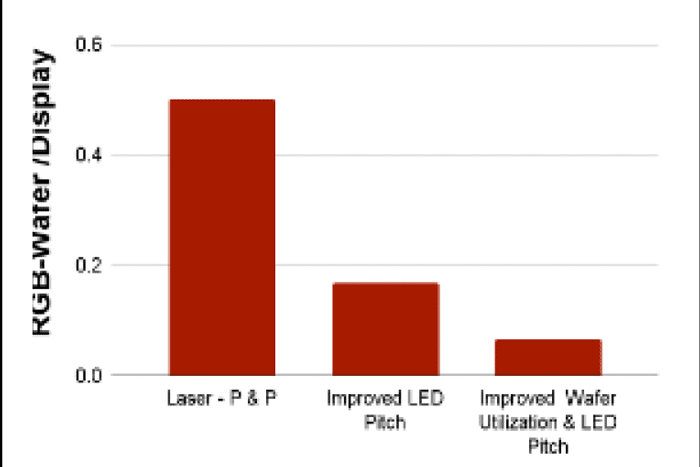

Up to 10x reduction in wafer usage

80% wafer utilization (compared to <50% for other solutions)

MicroSolid Printing™ is paving the way for widespread adoption of microLED display technology and life-changing micro semiconductor products.

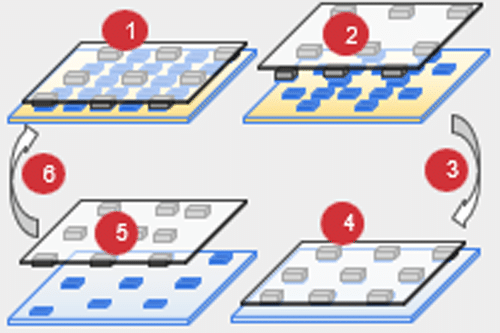

Laser Release

High Selectivity

Pick & Place (P&P)

Simple Tool

MicroSolid PRINTING™

Scalable • Affordable • Uniform

MicroSolid Printing™: Unparalleled Results

MicroSolid Printing™ addresses four key obstacles in microLED and micro semiconductor fabrication:High Yield

- Achieves rapid transfer of millions of micropixel devices.

- Delivers near-perfect yield with zero defects.

Unmatched Throughput

- Efficiently transfers millions of microLED chips.

- Outperforms traditional methods like laser and pick-and-place.

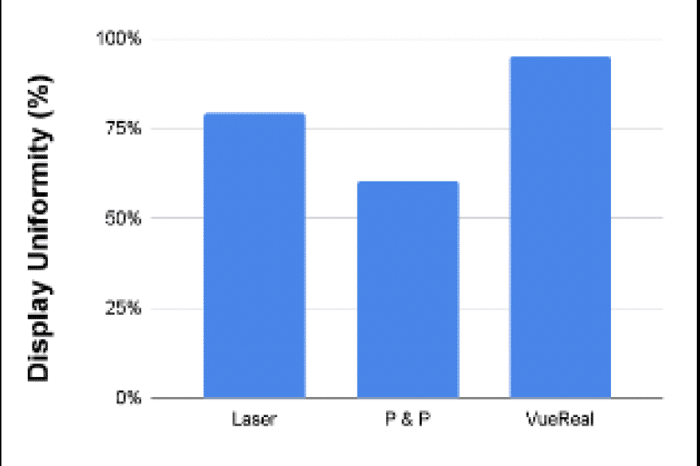

Superior Performance

- Overcomes wafer non-uniformity challenges.

- Achieves >80% wafer utilization (vs. <50% for traditional solutions).

Cost-Effective Integration

- Seamlessly integrates with existing fabrication processes.

- Enables transition to microLED or micro semi devices with minimal CApEX.

MicroSolid Printing™ advances both microLED displays and micro semiconductor applications, propelling industry innovation.

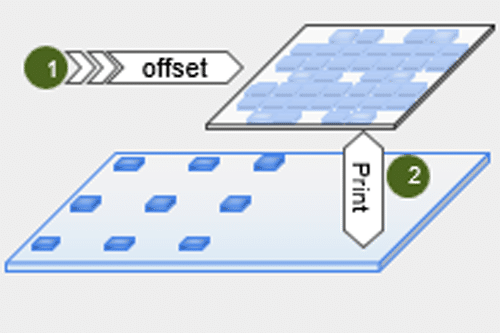

Material Cost

- 2-5x lower cost

- Enabling smartphone by meeting the cost and scale

Throughput

- 2x faster using similar tool

- 6x faster in our roadmap

Uniformity

- Managing non-uniformity

- Rendering more wafers useful

Want to learn more?